Top Market Share in Japan

Top Market Share in Japan

We flexibly respond to the needs of our customers as the top manufacturer in terms of deliveries in Japan.

These are additives for molten metal in the form of a long wire with various additives tightly covered by thin sheet metal or similar tape. We have developed wire for steel manufacture and wire for cast iron. These are widely used as the melt processing agent for various metals.

| Application | Category | Abbreviation | Main Filler Components |

|---|---|---|---|

| For steel manufacture | Calcium silicon wire | Calcium wire | Si and Ca |

| Sulfur wire | S wire | S | |

| Carbon wire | C wire | C | |

| Other special wires | - | AL, Bi, Mg and Si, etc. | |

| For cast iron | Spheroidizing wire | Mg wire | Si, Mg, Ca and RE |

| Inoculation wire | Si, Ba and Sr, etc. |

Iron coat thickness: 0.2 to 0.4 mm

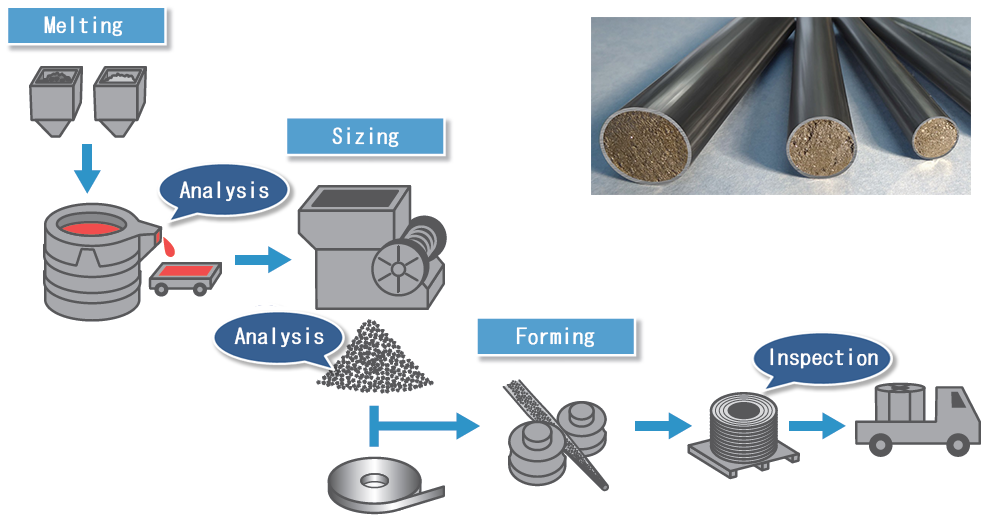

TOYO DENKA cored wires are wire-shape linear additives developed for molten steel in the steel manufacture process with metallic calcium, calcium alloys and other additives tightly covered by a thin steel plate. The wire injection method is a molten steel processing technique that allows additional components to be added stably with a high yield by adding cored wire to the depths of molten steel with a simple dedicated supply device.

This is a technique to add components stably with a high yield by adding cored wire to the depths of molten metal.

The magnesium wire method is a molten metal processing method to stably manufacture ductile cast iron.

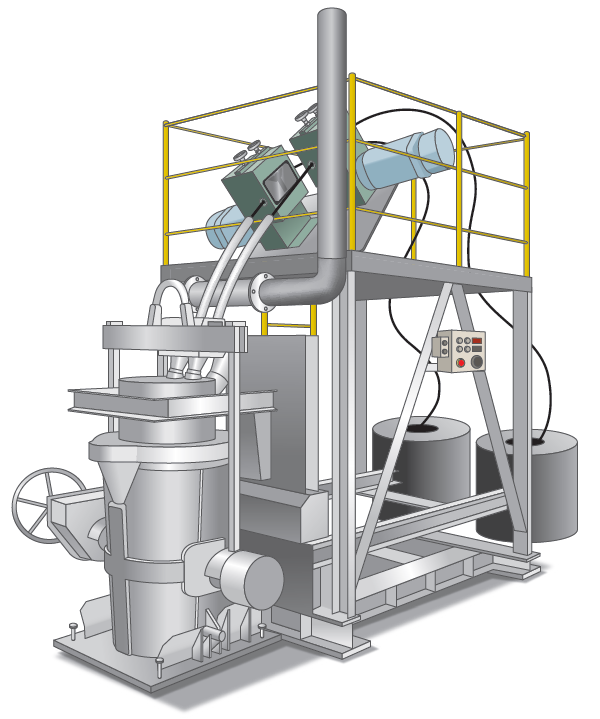

It is possible to add components stably with a high yield by adding cored wire to the depths of molten metal with a simple dedicated supply device (wire feeder).

In addition, this is a system with a great deal of flexibility in terms of dealing with fluctuations in the quantity of molten metal, controlling the target quality and automating facilities.